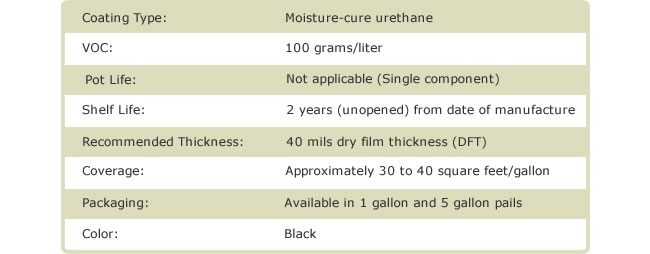

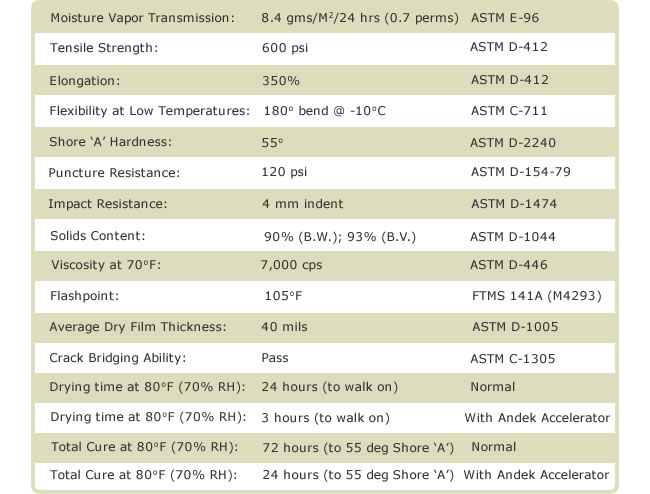

AIM #1 is a liquid applied urethane coating that forms a very tough, high performance barrier. It is used as a coating to protect and waterproof concrete gullies, docks and marinas, tile and concrete pipes, chemical safety dikes and wash-out basins. AIM #1 cures to a rubber-like finish that possesses excellent elasticity and will resist attack from the environment and from exposure to a wide variety of industrial chemicals.

|

|

||

- Provides a waterproof basecoat on concrete parking structures.

- Forms a tough, buried waterproof membrane beneath pavers, etc in plazas, balconies and outdoor recreation areas.

- Waterproofing below tank bottoms and fixed equipment

- Waterproofs basements, crawl spaces, tunnels, junction boxes and shower pans.

All surfaces to be treated must be at least 5° F above dew point and also clean, dry and free of all loose debris, oil, grease, and any other substance that would interfere with proper bond. A careful inspection of the surface should be made to detect any signs of damage or defects, and all repairs should be completed before application may proceed. Once preparation is completed, AIM #1 may be applied straight from the container after 3 minutes of low speed mechanical stirring. AIM #1 may be applied using a brush, roller, or airless spray technique at a wet film thickness of 30 mils. Andek recommends, in areas where reinforcement fabric is required, that Roofab (a specialty polyester fabric) be used. The fabric should be encapsulated between 2 coats of AIM #1 at a rate of 3-4 gallons per 100 square feet overall.

Application surface should be a minimum of 40°F and must be 5°F above dew point. Sudden precipitation will not wash AIM #1 off of the surface when wet or newly applied but will produce a mottled, dull appearance that is not detrimental to overall performance. If a faster setting time is needed ANDEK ACCELERATOR may be used (see technical Data Sheet for ANDEK ACCELERATOR)

Equipment may be cleaned after use with xylene or toluene before AIM #1 begins to dry.

Equipment may be cleaned after use with xylene or toluene before AIM #1 begins to dry.

Repair any damaged areas by following the instructions in the application section of this data sheet.

Protect AIM #1 from direct sunlight. This product is a moisture curing urethane and is packaged in specially sealed air-tight containers. If damaged, air and moisture may enter the container and cause premature curing. Cure time is 24 hours at 70°F (70% R.H.) as temperatures drop and at lower relative humidity set time is slower.

Read the container label warning and Material Safety Data Sheet (MSDS) for important health and safety information prior to the use of this product.

Keep out of reach of children and pets.

For additional information, contact our Technical Department.

Notice: The information presented herein is based on tests and data that Andek Corporation believes to be reliable. It is intended for use by technically qualified personnel at their own discretion and risk. Since conditions of handling and use are beyond our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. Nothing herein is to be construed as a license to operate or a recommendation to infringe any patent.