POLAJOINT SUPER is a 100% solids, polyurethane sealant that forms a flexible, elastic, chemical-resistant seal. POLAJOINT SUPER may be used in concrete, steel, or composite junctions and transitions. This product is designed to prevent the penetration of fluids through joints where movement may be anticipated.

Outstanding Features:

- Excellent chemical resistance to solvents, corrosives, oils, and salts

- High modulus, good elasticity, with rapid recovery and excellent fatigue resistance

- Superior mechanical properties with good resistance to impingement

- Provides good barrier properties to penetration by aqueous and non-aqueous fluids

- Good resistance to U.V. and thermal oxidative degradation

- Persistent adhesion to concrete, steel, and mineral composites under stress and shear conditions

- Pourable and self-leveling in horizontal joints

- May be modified with ‘K’ Catalyst for application into vertical joints

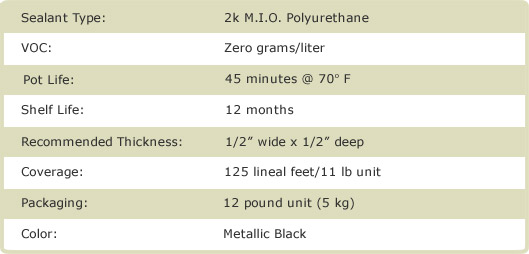

Specifications:

Application:

All surfaces to be coated must be dry and free of loose debris, oils, paints, grease, and other substances that would interfere with proper bond. Irregular width joints may need to be modified by grinding out to sufficient width to provide for modulus of elasticity. Shallow joints should have a bond breaker base of silicone tape or equivalent. Deep joints should be filled with backer rod or foam prior to sealing with POLAJOINT SUPER. Substrates that have insufficient cohesive strength, or may have been corroded, should be reinforced with a penetrating treatment of Polaprime 21. Horizontal joints should be sealed with normal unmodified POLAJOINT SUPER. Open the ‘B’ side container first and mechanically stir until all of the pigment has been brought up from the bottom and the contents are thoroughly homogenous. Open and pour the ‘A’ side (hardener) into the ‘B’ side container and mechanically stir until completely mixed, at least 3 minutes. Pour out the mixture into the joint so that the entire contents are dispersed along the area to be sealed. This provides maximum working time as the exotherm generated by curing is dissipated into the substrate. Overfills and spills should be corralled back into the joint with a spatula. Underfills and pockets should be topped off until it cures. Putty dams may need to be installed to hold the mixture in place so that it does not outflow.

Vertical joints should be sealed with POLAJOINT SUPER modified with ‘K’ Catalyst. Open the ‘B’ side container first and mechanically stir until all of the pigment has been brought up from the bottom. Add the ‘K’ Catalyst and mechanically stir until a heavy paste has been achieved and then open the container of ‘A’ side (hardener), stirring in thoroughly for at least 3 minutes. The mixture may be applied into the joint using a spatula, trowel, pump, refillable caulk gun, or other appropriate tool, following the same procedures as regular unmodified POLAJOINT SUPER.

Limitations:

Joint design may need modification to provide maximum longevity of sealant performance.

Precautions:

Read the M.S.D.S. in its entirety. Gloves, goggles, and barrier cream must be worn during application. Remove skin contamination as soon as possible with a resin remover. In case of eye contact, flush with clear water for 15 minutes and seek medical attention. If ingested, seek immediate medical attention.

Keep out of reach of children and pets.

For additional information, contact our Technical Department.

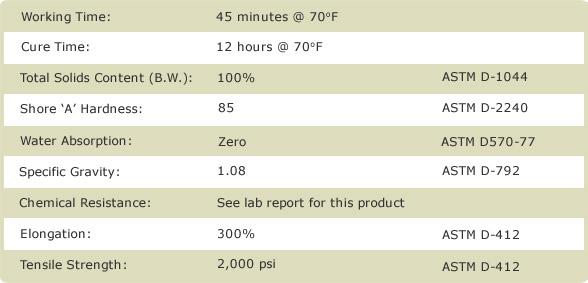

Technical:

Notice: The information presented herein is based on tests and data that Andek Corporation believes to be reliable. It is intended for use by technically qualified personnel at their own discretion and risk. Since conditions of handeling and use are beyond our control, we make no warranties, express or implied, and assuming no liability in connection with any use of this information. Nothing herein is to be construed as a license to operate or a recommendation to infringe any patent.