ROOFDX COPPER is an extremely tough, metallic, rubber-like, waterproofing coating that, being made with copper flakes, has a very attractive copper finish that will actually patina. This remarkable "liquid copper" coating can be used over all common roofing substrates and will give the appearance of copper sheet roofing at a fraction of the cost. Just like copper sheet, ROOFDX COPPER will develop a classic green patina, or may be sealed with Clearcoat 44 to maintain its new appearance.

|

|

||

Can be used over most metals, copper, rubber, concrete, modified bitumen, asphalt BUR, masonry, slate/tile, wood, and others.

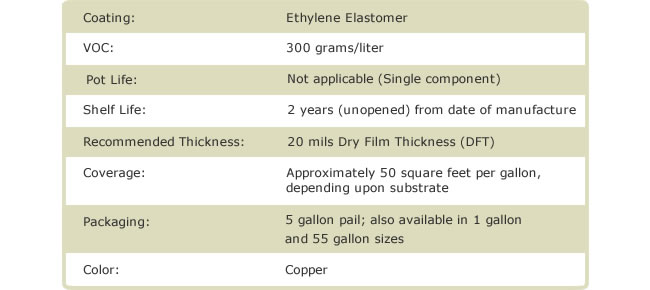

All surfaces to be treated must be clean, dry and free of loose debris that may interfere with proper bond. Surfaces that have previously been coated should be examined carefully and tested for adhesion to the substrate. This can be accomplished by applying a strip of scotch tape to the coated surface. The tape should be thoroughly pushed into full contact and then pulled away at a 90° angle. Observe the adhesive surface for any dislodged coating particles. If the tape has pulled away a significant quantity of coating, or if it has loosened the coating from the substrate, the coating should be removed. Loose coating should be thoroughly removed by abrasion, pressure washing or other available technique. Some coatings that are firmly bonded but have reticulated (mud cracked) and the edges lifted will need abrading to present a uniform, smooth surface for coating. Some very inert surfaces, such as epoxy, will require abrading and/or a special primer coat. ROOFDX COPPER is applied straight out of the can after 2 minutes of low speed mechanical stirring. Apply the product using brush, roller. or airless spray technique. The product should be applied in 2 coats at an overall rate of 50 square feet per gallon, achieving a wet film thickness of 30 mils or 15 mils per coat.

Clean tools and equipment with xylene or toluene before ROOFDX COPPER begins to dry.

Do not apply to frozen or saturated surfaces. Cold temperatures will slow down the drying time. Do not apply if precipitation is forecast within 4 hours after application.

Read the container label warning and Material Safety Data Sheet (MSDS) for important health and safety information prior to the use of this product.

Keep out of reach of children and pets.

For additional information, contact the Andek Technical Department.

Notice: The information presented herein is based on tests and data that Andek Corporation believes to be reliable. It is intended for use by technically qualified personnel at their own discretion and risk. Since conditions of handling and use are beyond our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. Nothing herein is to be construed as a license to operate or a recommendation to infringe any patent.