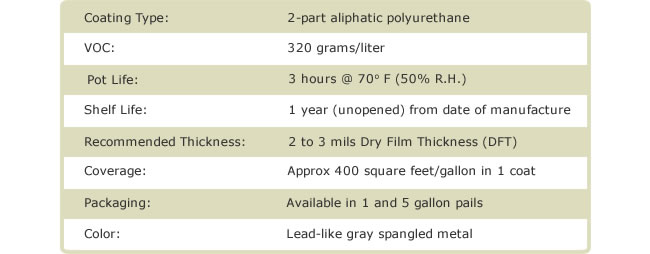

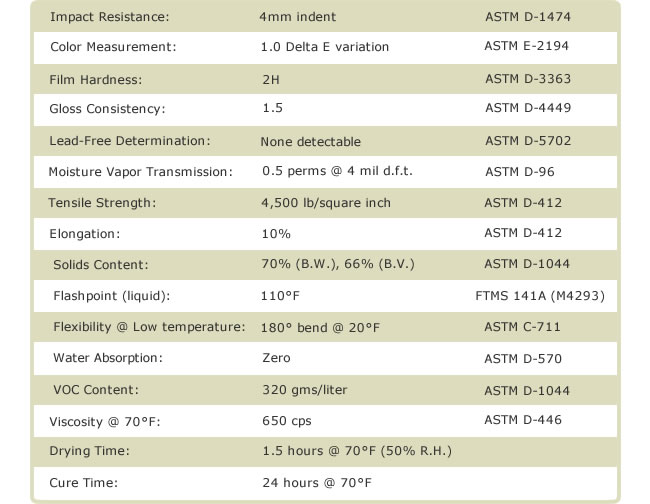

ROOFDX SL is a silicon-modified, aliphatic polyurethane coating that is extremely tough, flexible, and durable. The appearance of ROOFDX SL is similar to lead coated copper but does not contain any lead. ROOFDX SL is used as a finish coat over Andek products such as Polaroof NW, Polaroof RAC, and RoofdX Super, and in situations where the greatest similarity to lead coated copper is required, it may be used over RoofdX Copper. ROOFDX SL combines a unique mineral, micaceous iron oxide, with a blend of flaked metals including stainless steel to produce a dense complex barrier coating to protect against weathering, corrosion and chemical degradation. The surface of ROOFDX SL develops a silicon hammer finish which is extremely damage resistant and prevents dirt retention.

- Has the appearance of lead but contains no lead

- Provides a waterproof, durable, protective finish

- Retains its lead-like appearance and ages without discoloration

- Cures rapidly to form a flexible, tough and abrasion-resistant coating

- Resists impact damage without chipping or flaking

- Low energy surface helps prevent accumulation of tree resin and bird excrements

- Highly resistant to staining and deterioration from most chemicals

- Retains its dimensional integrity from cold through to hot temperatures

- Used as a finish coat over RoofdX Copper, it gives the appearance of lead coated copper for a fraction of the cost.

|

| This is a comparison of a surface coated with a RoofDX SL and a lead coated copper sheet. The RoofDX SL simulates a classic, lead coated copper appearance, yet contains no harmful lead. |

All surfaces to be coated must be clean, dry and completely free of loose particles, oil, grease, or any substance that would interfere with proper adhesion. ROOFDX SL may be applied over the products listed in the Description section at any time after they have set or cured thoroughly. It is important to test for “through-cure” as coating over a dry-to-the-touch surface may cause blisters in the basecoat through solvent entrapment. Once “through-cure” has been established by subjecting aggressive torque to the surface, application of the ROOFDX SL may commence. Add Part ‘B’ color concentrate into Part ‘A’ resin side and stir thoroughly for 3 minutes. ROOFDX SL is applied at a rate of 400 square feet per gallon in a single coat at a film thickness of 4 mils w.f.t. ROOFDX SL may be applied by brush, roller or airless spray technique in a thin even coat. As with any metallic coating, all brush strokes, roller or spray passes should be in the same direction so that the metal flakes within the coating orient themselves evenly for optical uniformity. Another important procedure is to stir frequently all mixed material to prevent settling of the metal flake pigments. Do not allow the mixed material to be contaminated with water or foam, bubbles and pinholes in the coating will develop. If this does happen, these defects may be sanded out and touched up once the coating has set thoroughly.

Equipment may be cleaned with toluene or xylene while the coating is still wet.

Store in a cool dry place away from direct sunlight. Avoid opened containers, as moisture will cure the material. Do not apply in temperatures below 35°F. Application must be protected from precipitation for at least 4 hours. Shelf life is 12 months when stored in factory sealed containers between 45°F and 85°F.

To repair damaged areas, sand thoroughly and remove all dust and dirt with solvent washing. ROOFDX SL may then be re-applied to the clean dry surface.

Read the container label warning and Material Safety Data Sheet (MSDS) for important health and safety information prior to the use of this product.

KEEP AWAY FROM CHILDREN AND PETS.

For additional information, contact the Andek Technical Department.

Notice: The information presented herein is based on tests and data that Andek Corporation believes to be reliable. It is intended for use by technically qualified personnel at their own discretion and risk. Since conditions of handling and use are beyond our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. Nothing herein is to be construed as a license to operate or a recommendation to infringe any patent.