ROOFDX SUPER is a single component urethane especially designed as a waterproofing membrane for all kinds of roofing. It cures to form a tough, elastic, waterproof seal and may be incorporated into roofing specifications that provide roof protection of 10 and 20 years. ROOFDX SUPER contains corrosion-inhibiting pigments and will protect metals against rust and acid rain.

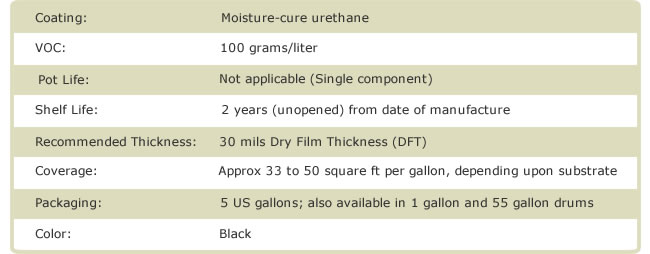

|

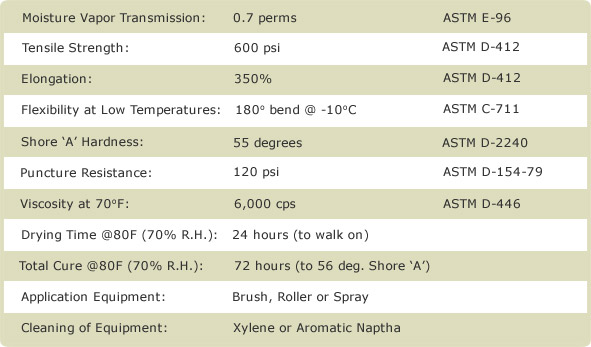

|

||

Can be used over BUR, asphalt or coal tar, EPDM, rubber, wood, concrete, brick, masonry, copper, steel, aluminum, tin, mineral composites and other surfaces.

Surfaces must be dry, free of dirt, loose debris, grease, oil, or any substance that could interfere with adhesion. Refer to POLAPRIME data sheet for information regarding selection of appropriate primer if necessary. Application over seams in metal roofs is achieved by embedding ROOFAB into a fresh coat of ROOFDX SUPER applied at 15 mils wet thickness. The fabric is then saturated with a second application at sufficient thickness to remove all voids, fishmouths and dry spots. Bolt heads on metal roofs should be daubed with sufficient ROOFDX SUPER that they are encapsulated to the point of rundown. As soon as the ROOFDX SUPER has dried, it should be coated with a compatible topcoat.

Application over built-up or modified asphalt roofs requires good preparation as described above. If gravel is present, this should be removed by wet-vac or scraped off and pressure washed. BUILDKOTE or compatible flood coat should be installed to soften the profile of embedded gravel. If the surface is slicktop, capsheet, or re-saturated, this should be vacuumed, blown or pressure washed until clean and, if excessively porous, primed with POLAPRIME 2. Application of ROOFDX SUPER may proceed by embedding 40” ROOFAB into a fresh coat of ROOFDX SUPER applied 1½ gallons per 100 sq ft (66 sq. ft. per gallon); the fabric should be smoothed out without stretching so that it conforms to the surface without voids, tents or dry spots. Begin at the lowest point of the roof and each roll saturated with an even coat of ROOFDX SUPER at 1½ gallons per 100 sq ft (66 sq. ft. per gallon) as soon as the first coat has soaked up and no wrinkles remain. Enough material should be present at the overlap that saturation occurs completely without fishmouths or dry spots. Continue application with laps facing downhill to shed water if work is interrupted by precipitation. Sudden precipitation will not wash ROOFDX SUPER off when wet or newly applied, but will produce a mottled, dull appearance that is not detrimental to overall performance. ROOFDX SUPER may be used as an adhesive at loose edges and will form all flashings and joints with the ROOFAB. Black surfaces, by their nature, will absorb heat; this heat buildup causes expansion, followed by contraction as the surface cools. This constant expansion and contraction causes fatigue of the substrate including the roof beams, fasteners, and other building components. To reduce the intensity of this cyclic fatigue and to reduce demand for air conditioning by lowering temperatures, a coat of a compatible solar-reflective roof coating is recommended. If solar panels or other overburden is to be installed, use appropriate separation layer.

Clean equipment with xylene or arothatic naptha.

Do not apply to wet or frozen surfaces. Store out of direct sunlight and away from open flames or other ignition sources. Keep containers tightly sealed when not in use. Shelf life is 12 months when stored in unopened containers.

Damaged areas may be repaired by cleaning surface and application of ROOFDX SUPER and Roofab as described in the Application section.

Read the container label warning and Material Safety Data Sheet (MSDS) for important health and safety information prior to the use of this product.

Keep out of reach of children and pets.

Notice: The information presented herein is based on tests and data that Andek Corporation believes to be reliable. It is intended for use by technically qualified personnel at their own discretion and risk. Since conditions of handling and use are beyond our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. Nothing herein is to be construed as a license to operate or a recommendation to infringe any patent.