Andek Firegard is a durable, waterproof, fire-retardant coating that forms both an ignition barrier and a thermal barrier. When exposed to fire, Andek Firegard expands to many times its original thickness. This generates a thermal insulating layer that protects the substrate from auto-ignition. In addition to its exceptional fire retardant properties Firegard is an extremely durable coating that waterproofs the coated surface. It withstands exposure to harsh outdoor weather and may be repeatedly washed without damage.

Andek Firegard may be used over all types of insulation, polyurethane foam, wood, wood composites, concrete, stucco, mineral composites, EIFS, bricks, masonry and other approved surfaces on the interior and exterior of buildings. This exceptional coating has been in constant use for over 30 years, protecting attics, crawl spaces, ducts, pipes, tanks, wooden structures, building components, boilers, and freezers in all types of climates. Firegard is listed by the Asbestos Information Center and the United States Government as an ideal sealant for encapsulation of low density asbestos lagging and asbestos insulation.

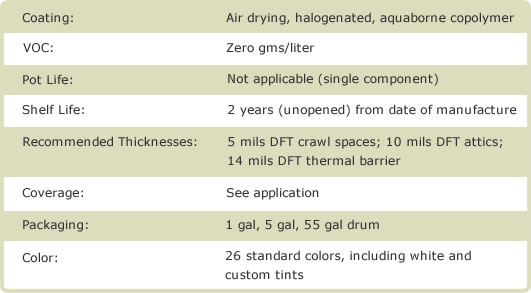

|

|

Recommended for:

Can be used over wood, wood composites, cellulosics, insulation materials, polyurethane foam, concrete, stucco, mineral composites, EIFS, bricks/masonry and other surfaces both on the interior and exterior of buildings.

All surfaces to be coated must be clean, dry and free of loose particles, oils, grease or any substance that would interfere with proper bond. A careful inspection of the surface should be made to detect any signs of damage or defects, and all repairs should be completed before application begins. Porous surfaces should be primed with Polaprime 2. Once preparation is completed and primer is thoroughly dry, ANDEK FIREGARD may be applied.

ANDEK FIREGARD may be applied using brush, roller or airless spray technique. Normal application for most surfaces will require 1 gallon per 100 square feet (16 wet mils = 10 dry mils). Where additional protection is necessary, two coats at 120 square feet per gallon per coat will provide an overall coverage of 60 square feet per gallon (27 wet mils = 17 dry mils). Tools may be cleaned using water while the product is still wet. If the material has dried, a suitable cleaning solvent may be used.

Tools may be cleaned using water while the product is still wet. If the material has dried, a suitable cleaning solvent may be used.

Do not apply to frozen or saturated surfaces. Protect product from freezing. Any exterior application should not commence or proceed when precipitation is forecast within 4 hours. Store out of direct sunlight.

Read the container label warning and Safety Data Sheet (SDS) for important health and safety information prior to the use of this product.

Keep out of reach of children and pets.

For additional information, contact the Andek Technical Department.

Notice: The information presented herein is based on tests and data that Andek Corporation believes to be reliable. It is intended for use by technically qualified personnel at their own discretion and risk. Since conditions of handling and use are beyond our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. Nothing herein is to be construed as a license to operate or a recommendation to infringe any patent.