SILI-THANE 803 is a low odor, one-part, gun-grade, moisture– curing polyether-based sealant. It has been specifically designed for a wide range of applications, including dynamically moving joints, bonding dissimilar materials, and sealing joints with varying coefficients of expansion. It cures to a medium-modulus rubber with extraordinary adhesion capable of accommodating joint movement of +25% of the original joint width. In contrast to urethane sealants, Sili-Thane 803 will not foam or bubble when exposed to moist substrates or high humidity conditions during cure.

Basic Uses:

Use SILI-THANE 803 for interior and exterior perimeter caulking of frame openings, expansion control and isolation joints, coping and coping-to-façade joints, cornice and wash joints, poured-in-place, panels, tilt-up, underside of precast planks, top of non-loadbearing walls, steps and risers, non-structural glazing, etc. It is also suitable for manufacturing uses, such as building travel trailers, mobile homes, extruded PVC windows and doors. SILI-THANE 803 has been tested and found to have excellent adhesion to unprimed aluminum, acrylic-coated aluminum, brass, steel, stainless stell, tin, concrete, mortar, granite, slate, glass, ceramic tile, fiberglass, ABS, PVC, Nylon 66, polyester, lauan wood and plywood. SILI-THANE 803 has been tested and found to have adhesive/cohesive failure-in-peel to unprimed polystyrene, polycarbonate and acrylic.

Outstanding Features:

- Superior UV resistance; does not yellow, crack, craze or chalk

- Very low odor for interior or exterior use

- Solvent– and isocyanate-free; low VOCs

- Nil shrinkage

- Minimal dirt pickup

- Non-gassing; will not foam or bubble

- Non-corrosive

- Paintable after cure

- Exceptional adhesion to wet or dry surfaces; good underwater adhesion to non-porous surfaces.

- Gunnable at cold temperatures

- Long life (20+ years)

Limitations:

- Should not be used for structural or butt glazing, nor in expansion joints less than ¼” in width or depth.

- Not recommended for use in water immersion applications on porous substrates

- Not for use on absorptive surfaces such as marble, limestone or granite without prior testing for discoloration or staining. Testing has shown that Sili-Thane 803 is less likely to cause staining than silicones or urethanes.

- Sealant must be fully cured before painting. Recommended paint is acrylic latex. Some solvent-based alkyd and acrylic paints may not adhere or cure properly. Any paint to be used should be tested on the sealant before using.

- Not for use in any application to be immersed in organic solvents.

- For applications on glass where the sealant is exposed to strong UV, a primer is required.

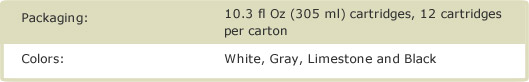

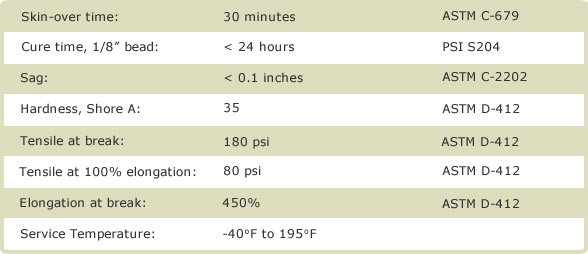

Specifications:

Applicable Standards:

SILI-THANE 803 meets or exceeds the requirements of Federal Specification TT-S-00230C, Type II, Class A; ASTM C920, Type S, Grade NS, Class 25, Use NT, G, M, A, and O; CAN/CGSB 19.13-M87.

Installation:

Joint Design: The width of the joint should be a minimum of 4 times the calculated joint movement. Minimum allowable joint width or depth is ¼”. In joints up to ½” wide, sealant depth should be equal to the width. In joints wider than ½”, the depth should be maintained at ½”. Joints should not exceed ½” deep and 1” wide.

Surface Preparation:

Joints to receive sealant must be clean, sound, dry, smooth, uniform in dimensions, and free from defects, frost and all contaminants such as waterproofing sealers, curing compounds, coatings, etc. To test adhesion, apply a bead of sealant and allow to cure thoroughly. Then pull one end of the bead to test adhesive strength. Protecting the top joint edges with masking tape will help make a nicer looking job.

Priming:

SILI-THANE 803 has excellent adhesion to most common, firm, uncontaminated materials. In Some applications it may be prudent to use a primer; i.e., concrete that is friable, frequently wet or sandy, and some plastics. Because substrate composition and condition varies, any sealant/primer combination should be tested before use.

Backup Material:

The purpose of backup material is to regulate the joint depth; to provide a surface against which the sealant is compressed when tooled, thus promoting better adhesion to the side walls; and to provide a non-adhering back surface, precluding the possibility of a 3-sided joint. Where backup material is not necessary or where a type is used that does not have release properties, a bond-breaker tape should be used. Closed-cell polyethylene foam backup material is recommended. It should not be twisted, punctured or excessively stretched during installation, nor should it be compressed more than 50% its original diameter. Open cell backer rod is compatible with Sili-Thane 803 as long as it remains dry.

Application:

For adhesive applications, apply sealant and press surfaces together firmly. For sealant applications, install backing material, apply sealant, and tool surface for maximum surface contact. Air temperature and humidity at time of application has a direct influence on work life and cure speed. Drier, colder climates require more cure time. Immediately wipe away excess sealant and smears with xylene or mineral spirits. For equipment cleanup, use solvent equivalent to xylene or mineral spirits. Consult manufacturer’s MSDS for safety precautions prior to using solvents. Shelf life is 1 year from date of shipment when stored in original, unopened container in a dry area at temperatures below 80°F.

Maintenance:

If the sealant is damaged and the bond is intact, cut out the damaged area and recaulk. No primer is required. If the bond has been affected, remove the old sealant, clean and prepare the joint according to instructions under Surface Preparation.

Technical:

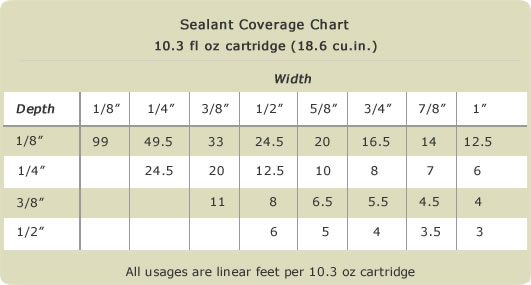

Coverage:

Silithane 803 is a trademark of Polymeric Systems, Inc.

Notice: The information presented herein is based on data that Andek Corporation believes to be reliable. It is intended for use by technically qualified personnel at their own discretion and risk. Since conditions of handling and use are beyond our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. Nothing herein is to be construed as a license to operate or a recommendation to infringe any patent.