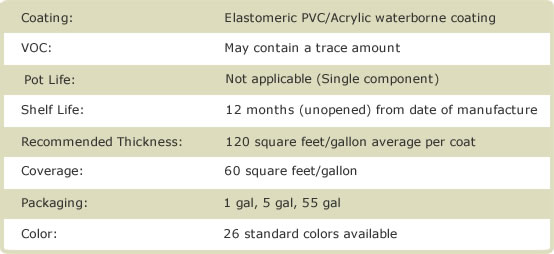

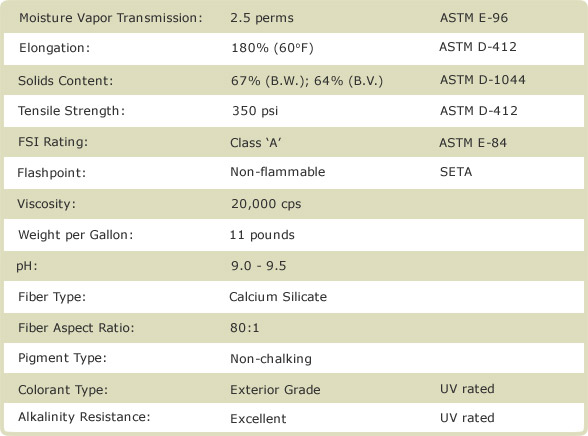

POLAGARD FIBRELASTIC is a single component, premium quality elastomeric wall coating designed for permanent flexibility and toughness. It will accept movement from thermal changes and bridge hairline cracks. POLAGARD FIBRELASTIC provides a waterproof finish that is both decorative and long-lasting, and it may be applied directly to most surfaces including concrete, splitface block, brick, stucco, wood, asbestos shingles, concrete block, mineral composites and precast concrete.

|

|

||

Surface must be firm and free of dirt, efflorescence, oils, grease, loose debris or any other substance that may interfere with bond. It is advisable to have a dry substrate. If the surface is damp, test the surface first by applying coating to a 4' x 4' area. If no sags or runs occur within 30 minutes and the coating appears to be taking a normal cure, application can proceed. Previously coated or treated surfaces must be tested prior to application to insure proper adhesion. It is advisable to fill any heavily pocked, spalled or broken areas of substrate. Repair cracks greater than 1/16" with a premium grade of acrylic caulk. Mound the caulk slightly so that the repair is flush with the wall surface and allow to cure 4-6 hours. Apply FIBRELASTIC over repaired areas. FIBRELASTIC may be brushed, airless sprayed, or rolled. For airless spray, be sure to use a reversible tip (a #35 orifice is a recommended starting tip). For roller application, a l¼” nap roller provides good results. The nap thickness can be varied to accommodate the substrate. FIBRELASTIC may be thinned with no more than 3-5 oz. of water per gallon. For waterproofing, apply 2 coats at 15-20 mils thickness per coat. When spray applied, it is advisable to backroll the first coat to insure optimum weatherproofing and reduce pin holing. Power stir product for 2 minutes at low speed before use. Always apply to the shaded areas of the building with ambient surface temperatures. Unshaded areas may have high surface temperatures that can cause rapid skinning of the coating and blisters may appear.

Do not apply to frozen or saturated surfaces. Do not apply if temperature falls below 45° F. within 4 hours unless an artificial heat source and enclosure are provided. High humidity and precipitation interfere with application and adhesion. Do not apply if rain is forecast within 8 hours of application completion. Shelf life in unopened containers is 1 year at 45° - 90°F. Protect FIBRELASTIC from freezing. Keep containers sealed and under cover when not in use.

If a treated surface becomes dirty, spray with water or a mild soapy water solution. Rinse with a clean, low pressure water spray. For scars or hard-to-clean areas, recoat with FIBRELASTIC.

Read the container label warning and Material Safety Data Sheet (MSDS) for important health and safety information prior to the use of this product.

Keep out of reach of children and pets.

For additional information, contact the Andek Technical Department.

Notice: The information presented herein is based on tests and data that Andek Corporation believes to be reliable. It is intended for use by technically qualified personnel at their own discretion and risk. Since conditions of handling and use are beyond our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. Nothing herein is to be construed as a license to operate or a recommendation to infringe any patent.